The Application of Roller Presses in the Cement Industry

Release date:

2022-03-09

Author:

Source:

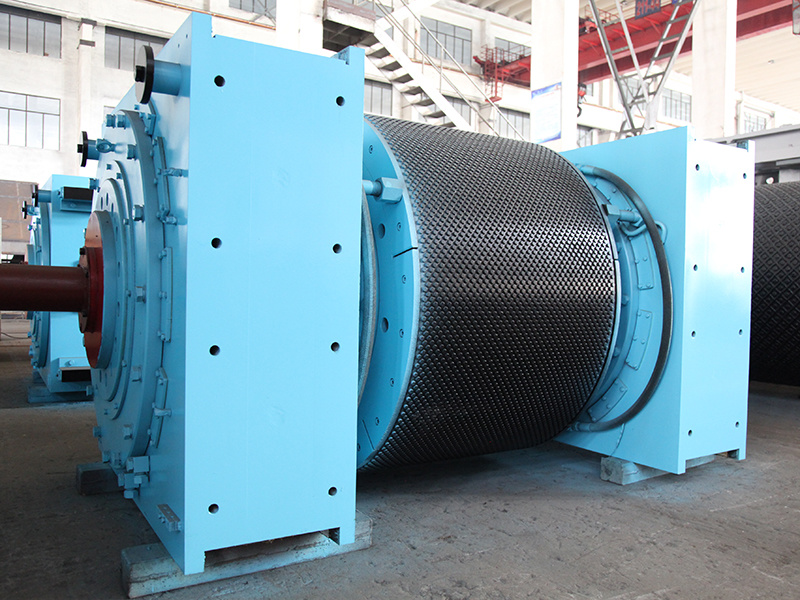

The roller press is designed based on the principle of料床 (material bed) grinding, and its key features include: high pressure, full-speed operation, full-material loading, and material-bed crushing. The roller press consists of two counter-rotating, synchronously moving compression rollers—one fixed and one movable.

Materials are fed in from above the two rollers and continuously drawn into the gap between them by the squeezing rollers, where they are subjected to 100-150MPa After being subjected to high-pressure action, the material transforms into a dense cake that is discharged from beneath the machine. The discharged cake not only contains a certain proportion of fine, finished particles but also develops numerous cracks within the non-finished particle structure. This significantly enhances the material's grindability, and during subsequent crushing processes, it can lead to a substantial reduction in grinding energy consumption.

The conventional roller press consists of a frame, two roller sets, a drive mechanism, torque bearings, roller covers, a feeding device, and a hydraulic (pressurizing) system. Main bearing It consists of components such as the lubrication system, dry-oil lubrication system, electrical system, and roll-unloading mechanism. In addition to the main parts and mechanisms found in conventional roll presses, the precision roller press incorporates advanced devices designed to ensure high rolling accuracy.

Practical Application Results of Roller Presses in the Cement Industry Having the following Features:

( 1 ) Enhancing productivity: Installing a roller press in the grinding system, where its high-pressure load is transmitted through the dual roller diameters directly onto the material layer being ground. Most of the energy is utilized for the mutual compression among particles, while the acoustic and thermal energy generated by particle friction is converted into deformation energy, causing the materials to deform, tear, and ultimately crush. This process fully unlocks the potential capacity of the grinding equipment, leading to a significant increase in production— 50-100% , total energy consumption can be reduced 20%-30% , which has boosted the overall productivity of the system.

( 2 ) Reducing energy consumption: Use a roller press to grind materials. Not only does the particle size of the material significantly decrease after roller pressing, but the Bond work index also drops noticeably, greatly improving the grinding conditions in the subsequent mill and leading to a substantial reduction in specific energy consumption across the entire grinding system. This approach can significantly lower the overall energy usage of the grinding system, offering substantial energy savings compared to conventional grinding methods. 25-50% , the annual energy-saving benefits are quite significant.

( 3 ) Cost-saving investment: Compared to tube mills with the same production capacity requirements, roller presses feature a simpler structure, smaller footprint, and lighter weight, occupying less factory space. This not only helps save on civil engineering investments but also makes it easier to retrofit existing grinding systems. Additionally, operating and maintaining roller presses is remarkably straightforward.

( 4 ) Excellent working environment: Materials are continuously and steadily crushed within the extrusion roller housing, preventing harmful dust from easily spreading. Additionally, since virtually no impact occurs, the noise level of the roller press is significantly lower than that of a tube mill.

( 5 ) Easy to develop: Traditional tube mills are limited by factors such as processing, transportation, and heat treatment. Tube mills Large-scale implementation faces significant constraints. However, the roller press grinding system effectively addresses these challenges, making it possible for grinding systems to move toward larger-scale operations.

Related News

What are the advantages of carbide threaded drill bits?

2025-09-20

How to effectively improve the surface precision of workpieces?

2022-07-05

Things to keep in mind when using carbide hob cutters!

2022-07-05